Written by Marloes

Edited on

11 August 2023

·

11:45

Advice on drill bits

It's important to choose the right drill bit for your job. But which drill bit is suitable for your drill? And which one is the most suitable for the job? In this article, we'll explain what you should keep in mind.

Choose a drill

It can be difficult to choose the right drill. You should keep 2 things in mind:

- Type of drill head

- Material you want to drill into

Quick release

A quick release drill chuck is the most common type of drill chuck. With a quick release drill chuck, you have to screw the drill bit into the drill chuck manually. The drill bit is firmly lodged into the drill chuck thanks to the quick release system. As a result, they won't fall out during the job. Quick release drill chucks are usually suitable for drill bits between 1.5 and 13mm. Especially screw drills and hammer drills work with a quick release system.

SDS drill head

There are 2 types of SDS drill chucks: SDS-plus and SDS-max. An SDS-plus drill chuck has a shaft, into which you click the drill bit. Thanks to this, it won't slip out of place. This is important for heavy drilling jobs. An SDS-max drill chuck works the same way as an SDS-plus drill chuck, but an SDS-max drill chuck can handle even more demanding jobs. You mainly use this type with demolition hammers and hammer drills. If you want to purchase one, keep in mind that the different SDS-types aren't interchangeable.

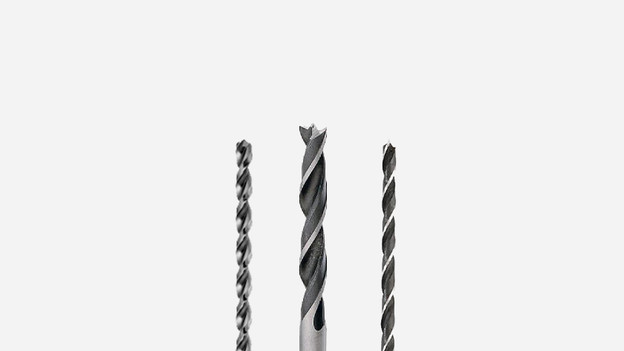

Wood

You can recognize the most common wood drill bit by the sharp tip, which is the center tip. This allows you to drill in wooden surfaces very accurately. You can also drill into materials like plastic with a wood drill bit. Other common wood drill bits are the auger drill bit, spade drill bit, countersink, and hole saw.

Metal

You can recognize a metal drill bit by the very sharp tip you use to drill into the hard material. Without this sharp tip, you'll slip and damage the material. The drill bit removes the metal scraps it release while drilling via the round shaft. Metal drill bits differ in hardness. For soft metals like copper and aluminum, a regular steel drill bit will do. For hard metals like stainless steel, use a metal drill bit made of Indigo or titanium-carbide.

Stone

If you want to drill into stone or brick, you need a masonry drill bit. You can recognize these drill bits by the 'wings' on the tip. They also have a blunt tip just like concrete drill bits, so a lot of force can be used to drill into the stone material. The difference with concrete drill bits is the material of which the stone drill bits are made. You can't use a stone drill bit in concrete, the material of the drill bit is too weak for this. You can use stone drill bits in combination with a drill or impact drill.

Concrete

Drilling into concrete is impossible if you don't use a concrete drill bit. Concrete is rock hard material that you can't just use any drill bit for. Concrete drill bits are blunt and have a blunt tip with wings that work like a chisel. The tip is made of extremely hard material, like tungsten carbide or widia (from the German wie diamond). You can use a concrete drill bit in combination with a drill or combi hammer.

Article by Marloes

Drill Expert.