Written by Nathalie

Edited on

3 December 2024

·

15:08

4 tips for drilling in metal

If you want to drill in metal without damage, it's important to keep a few things in mind. This helps you prevent ugly scratches, dents, or a burnt drill bit. In this article, we'll give you 4 tips to successfully drill in metal. Choose a low speed and use a metal drill bit, for example.

Get started with drilling in metal

Drilling in metal isn't difficult, but requires some attention. Follow these tips:

Tip 1: choose the right drill bit.

Tip 2: prevent slipping.

Tip 3: use a low speed.

Tip 4: cool with drill oil.

Tip 1: choose the right drill bit

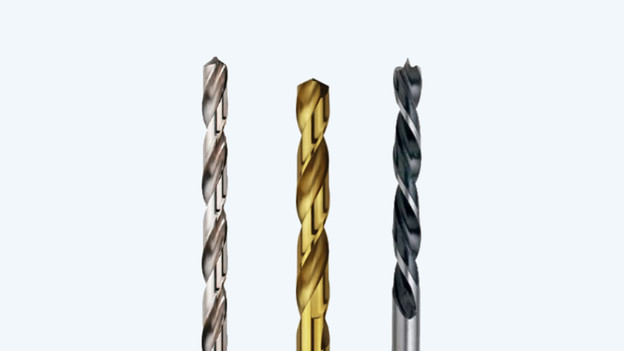

There are different types of drill bits for different materials. There's also a special drill bit for metal. You recognize a metal drill bit by it's spiral shape and sharp tip. This tip lets you easily drill through metal and exactly in the right spot.

Tip 2: prevent slipping

Because metal is often smooth, there's a good chance your drill bit will slip. This can leave behind an ugly scratch. You can prevent this by first making a small dent in the metal. Do this with a center punch or a nail. You can then place the drill bit in the dent. Do you want to be 100% sure your drill bit won't slip off? Use a pillar drill, this machine is very precise.

Tip 3: use a low speed

Due to friction while drilling, the metal becomes very hot. The larger the hole you drill, the larger the resistance and the hotter the material gets. A high speed also causes for friction, which again causes more heat. That's why you should use a low speed. Are you drilling in stainless steel with a 5mm drill bit? Use a speed of up to 600. With softer metals like aluminum, use a speed of 1500. Always start low and slowly increase the speed when necessary.

Tip 4: cool with drill oil

Metal becomes very hot while you drill. Sometimes, this heat makes the metal harder. This makes it more difficult to drill through the material. This happens with stainless steel, for example. With drill oil, you can cool down the metal and your drill bit. This way, the metal doesn't become harder and your drill bit remains sharp.

Article by Nathalie

Drill Expert.